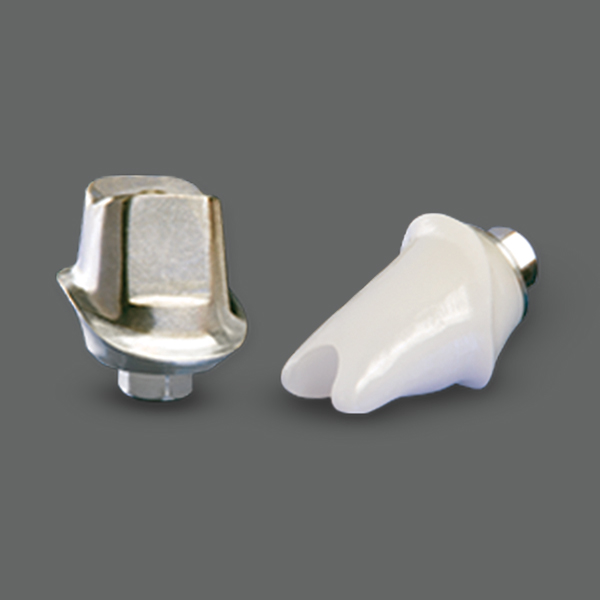

Smith-Sterling offers two types of custom implant abutments under the Inclusive® brand name. Inclusive Custom Implant Abutments are available in titanium and zirconia with titanium base to fit your patients’ individual needs. Titanium abutments are commonly used in all regions of the mouth due to their strength. Zirconia abutments include a titanium base, provide the best possible esthetics and are commonly used in the anterior with all-ceramic or zirconia restorations

Inclusive Custom Implant Abutments are precisely milled using CAD/CAM technology to facilitate a natural-looking emergence profile and optimize soft-tissue contours and crown esthetics. This precise interface also ensures comfortable delivery of the final restoration and excellent gingival health. Inclusive Custom Implant Abutments are compatible with up to 21 of the most popular implant systems.

Use manufacturer’s tooling to remove healing cap. For multiple units, start in the posterior and work toward anterior. Then, use manufacturer’s tooling to place transfer coping. Ensure components are fully engaged before tightening screw. Take an X-ray to verify proper seating of components. Next, ensure transfer coping does not hit tray. Use heavy body vinyl polysiloxane impression material. Record impression. Finally, when impression tray is removed, the transfer coping stays in the mouth. Remove transfer coping, and replace healing cap. For multiple units, start in anterior and work toward posterior. Check fit of impression coping into impression. Send to lab.

Seat abutment. Torque screw into place per manufacturer’s recommendations. Next, use composite to fill over the implant screw. Cement restoration over implant with a resin-reinforced ionomer (e.g., RelyX™, 3M ESPE).